Loading... Please wait...

Loading... Please wait...All prices are in All prices are in AUD

Categories

- Home

- Blog History Revisited

- "City of Adelaide" Clipper Ship - What is Old Is New Again

"City of Adelaide" Clipper Ship - What is Old Is New Again

Posted by ©Sandra Ker Antiquarian Print Gallery 1989-2022, South Australia. www.historyrevisited.com.au on 31st Dec 2022

Back to the Future

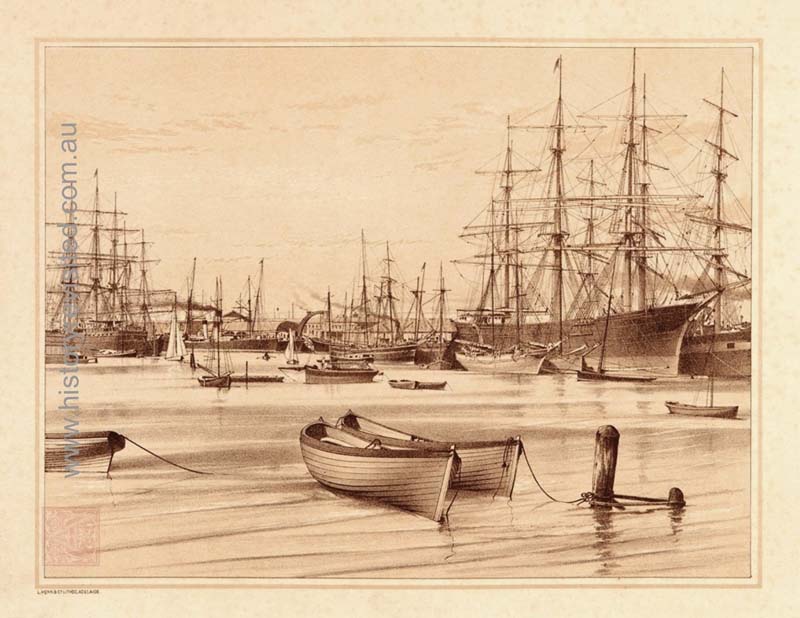

The City of Adelaide clipper, with her sister-ship, the Cutty Sark, represent the last of the commercial ridgy-didge sailing ships that utilised renewable wind power to get cross oceans. As the only surviving composite hulled sailing ships, they are constructed at the end of a 60 year window between timber Napoleonic wind-powered oak First Rate Battleships and the steam-powered metal begemoths. Both had an anticipated life of 25- 30 years, but somehow have survived a scrap yard fate. The Cutty Sark, as a tourist attracting, history-celebrating, money generator in front of the Greenwich Maritime Museum, London. TICK. The other? Forgotten on a lonely, cold, silted slipway on the Irvine River ("Please Sir, where's that?", "Why laddie, that is in South West of Scotland") . City of Adelaide clipper, after 22 years of loyal service, was decommissioned, to continue as a WWI hospital ship, WWII female billet accommodation & a Naval Officers Club, just before the hull leaked and she sunk…twice. It was the Scottish Maritime Museum wishing to emulate the success of its English counterpart, that retrieved the hull destine for further purposeful reinvention. Problem was the memo to pay the agreed storage fee was habitually lost. By 2007, the land owner took decisive action in the form of a demolition order. Enough was enough! Now the gloves came off, as interested parties garnered their resources...

Clipper's New Home, Port Adelaide

Enter the long and winding road of South Australian action group, “Bid to save the City of Adelaide”. The Late Prince Philip was their knight in shining armor to sway push the pendulum in South Australia’s direction. The nail-biting continued with an epic journey of the City of Adelaide hull on the M/V Palanpur in February 2014. The determined efforts of the many dedicated South Australian volunteers achieved this remarkable outcome, though many detractors thought it impossible. Maybe this is Lesson One = DON’T GIVE UP

The actual city of Adelaide now has this colonial life-savor in Port Adelaide, a port it had known so well. Why? Lesson Two: Because it was built before the concept of “Designed Obsolescence”. As action group saviors seeks a once-and-for-all permanent home for this amazing chunk of visual history, let’s see what we can learn about survival. Humanity is always in need of that.

LESSON ONE: The Original "Recycled" Paper

Well into the 20th Century Rag 'n Bone Men patrolled the city streets to gather unwanted recyclable goods to sell to manufacturers. Let's see a few examples: animal skin/tenders/bones for glue makers, animal bone orPotter's Bone China, rags for paper makers

Ask most people today what paper is made of, and the answer would be “Trees”. However, was an 18th century poem,"Rags make Paper, Paper makes money, Money make Banks Banks make loans, Loans make Poverty, Poverty makes Rags"

Before 1883, over 75-90 % of paper was made with hemp & flax products. This was often in the guise of worn-out clothes, curtains, diapers, old hemp fishing lines and worn sail-cloth. Now, SAIL CLOTH is the focus of this third lesson. Wind fatigue, salt and canon balls took their toll on these vital air-catching membranes. They were costly to make so ship owners sold them to scrap dealers, or “Rag ‘n Bone Men”. In an age of limited resources, if it was not fit for its original purpose, there was a thing called "mend and make-do", and the yesteryear “steptoes” will attest to money in "them-there cast-offs". Cloth was a primary resource of paper production. Rag paper was the epitome of the phrase ‘waste not want not’. Laid paper was the most stable and durable paper ever made. Problem presented in the labor intensity required limited its production. Warning! “Red Herring”- Just think, if they could genetically test rag paper to identify sails that had once been used by Captain James Cook’s discovery of Australia’s East Coast on the “Endeavour”, or Sir Horatio Nelson’s Battle of Trafalgar's “Victory” (I’m just saying...). Paper making techniques did change but rag made of flax and hemp was a constant. Well that was about to change with big consequences. The source of the problem to be solved was the adaption of steam power to solve the problem of more reliable maritime trade and human transport.

LESSON TWO: Stable Rag to Unstable Wood Paper

The Demise of the Tallship was predicated by the success of Steam Engine technology.

Don’t forget, the clock of history is ticking. We are in the heady cross-hairs of the Industrial Revolution meets the Enlightenment, each eagerly feeding the other. The Merchant Class (the modern Middle Class), saw the opportunity to equal, if not surpass, the wealth and power of the nobility. They competed with each other to predict problems that they could solve to gain wealth. What if this steam power thing takes off? Where will paper makers get their critical mass of supply to feed the ever-growing demand of the Printing Industry, which was satiating the demand of an increasingly literate and growing world population? Remember, we can ONLY go forward…

Turns out an enterprising German inventor, Frederick Gottlob Keller, was ahead of the crowd to solve the anticipated decline of sailcloth. He had invented the machine that set about testing more readily available resources. It was generally thought that trees were an inexhaustible resource were they not? Keller’s machine settled on softwood conifers. "STOP THE PRESS, Major Marketing Coup: the primary source was inexhaustible, (isn't it?) and here is the kicker, it is cheaper". Merchant bottom-line bean-crunchers rejoiced! So this is the story of how wood pulp paper became the default source for the printing industry after 1883. Little did Keller know he had cast the pebble causing a tsunami wave of aging lignin acid for twentieth-century Libraries of the World.

“What causes yellowing paper in some books but not others? What is this Evil Menace?" It is a necessary resident of botanical resident in tree cells that ensures the battle with gravity is won every day, Lignin. "How can we prevent our depositories of knowledge from dissolving into mounds of dust?” In the mid-1980s I worked in Book Orders at a University Library and spent a good amount of time decommissioning books. They were destined for the foreseeable future, to live in a purpose-dug hole to act as a cellar does for fine wine. Here the optimum temperature would hopefully buy the time needed until we can afford to employ the solution.

The happy postscript to this conundrum was the WORLD-WIDE WEB. Ignoring all of the annoying conspiracy theorists, spam, trolls and Cybercriminal activity, it has been a savior of knowledge, especially if you type in the best KEYWORD for the answer you seek, “which brings me back to the beginning…” where we began this Blog Lesson…

LESSON No.3 : Why Cotton & not Hemp & Flax Archival Paper?

In the 1990s, such bodies as the Library of Congress in the United States were leading the way in research into the cause of paper degradation. As an Antique Print & Map dealer, it made sense to source conservation frame presentation materials to preserve finite treasures, and the intrinsic value of all Art. e cotton mat boards seemed like a naturally superior fit. However, why have Flax and Hemp, the mainstay of past high-quality hand-made paper, been ignored? It turns out that hidden agendas may have much to answer for on this front. Finance Empire Builders like Dupont and Hearst Paper Manufacturing, were primarily responsible for their demise. They had Petroleum monopolies, their choice of plastic-making product. But it turns out the first "plastic" was made using the Hemp plant. It was easy to condemn all four strains of cannabis by citing the THC-psychoactive evils of Cannibis indica. Cotton requires large quantities of freshwater making it unsuitable for any but lands of high rainfall. As proposed by hemp advocate, Professor John Jingles, Flax and Hemp were the most valuable plants the late 1700s due to Naval and Maritime trade demands. Now its value is the adaptability for agriculture as both plants require 25% water per crop. High water requirements of Cotton in Australia, for example, Cubby Station, have majorly stressed the Murray/ Darling river system impacting on the environment, the nature it supports, and other vital food producers. The different features of both plants can make fabrics, archival paper, construction materials, and oils useful in industry as an alternative to petro-chemicals eg linseed oil prevents the incidence of rust on machinery while in the diet, and provides Omega essential fatty acids so has medicinal qualities as well

LESSON No 4 : Wind Power Lessens Carbon Output

With Global concerns about the Human Carbon Output and its effect on climate change (also read the opinions of Ian Plimer in "Heaven & Earth" ), the cargo ship operators sought a way to reduce the cost of producing that carbon by burning the crude fossil fuel necessary to power this huge craft. In the Sydney Morning Herald January 23rd, 2008, the MS Beluga, the world’s first modern cargo ship, set sail from Germany bound for Venezuela partially powered by a 160-square-meter GIANT KITE (now where have we seen that before?)

“During the next few months we will finally be able to prove that our technology works in practice and significantly reduces fuel consumption and emissions,” said Stephen Wrage of Skysails. The huge vessel is pulled along by a computer-controlled kite attached to the bow of the ship. The computer regulated the sail efficiency retracting it when wind conditions changed hence achieving the optimum benefit. The result was the kite and modern technology attached to it assisted the engine, reducing fuel consumption by “up to 35 percent depending on the prevailing conditions”

- a) Reduces Carbon output hence the amount of Offset when Carbon trading is introduced

- b) Saves money in fossil fuel costs

- c) Proves that what worked for humankind for centuries is still relevant and can be made more efficient by applying modern technology.

- d) History and the future are symbiotic. If all the generations get together just think of what can be achieved!

CONCLUSION.... and the biggest lesson

Most lessons have already been practiced and the results, beneficial or not, are recorded by Historians. As an Antiquary specializing in prints generated by the inhabitants of the past, and a practicing Conservation framer, I maintain Conservation is more cost-effective than Restoration (and designed obsolescence = landfill and pointless waste)

History is a noble teacher: as it is revealed to us we can chuckle at being unaware and benefit from the knowledge it imparts.

Recent Posts

- » Schomburgk's Botanic Garden & Park Plan, 1874

- » "City of Adelaide" Clipper Ship - What is Old Is New Again

- » Napoleon, Hudibrastic Poetry, Doctor Syntax & the Power of Satire

- » Colonial Melbourne to Albury "Parlour Car" Photo Connects to Adelaide Past & Present

- » May Gibbs: Successful Business Woman